Automotive Molds

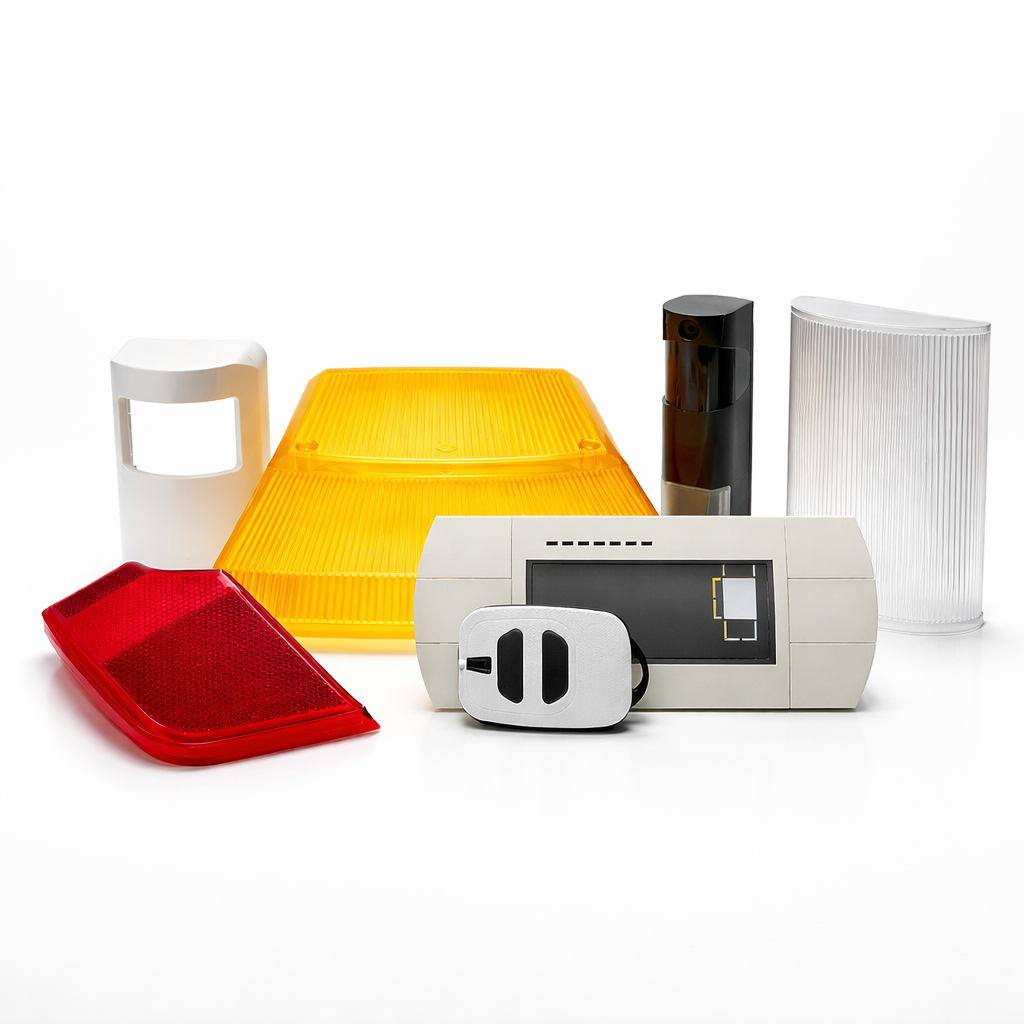

Fesp Mold makes high-precision, small and medium-sized moulds (max 1000x800mm) for plastic components for the automotive industry. We collaborate with automotive suppliers and manufacturers to develop robust, durable and optimised moulds for series production. We offer reliable solutions for the manufacture of optics, cable insulators and connectors, brackets and other functional or aesthetic technical elements.

//

Types of Components

We design molds for a wide range of automotive applications:

- Interior and exterior technical components Headlamp and taillight optics

- Cable insulators, connectors and fasteners

- Solutions also bimaterial (2k) and trimaterial (3k)

- Covers and housings

- Mounts and supports for electronic systems

//

Performance and Reliability

Our molds are built for:

- High repeatability in production cycles

- Optimized cycle times for large batches

- Compatibility with filled and technical polymers

- Durability and easy maintenance

//

Applications and Clients

We’ve developed molds for Tier 1 and Tier 2 automotive suppliers. Each project is handled in close collaboration with the client's R&D and production teams to meet strict dimensional, functional, and aesthetic requirements.

//

Why Choose Fesp Mold

- Proven expertise in complex automotive molds

- Integrated production thanks to Industry 4.0 protocol - Cad+Cam+ERP+MES

- Multicavity options for high productivity

- Dimensional quality control and testing

//

Some automotive and home automation items made with our injection molds