Quality control and testing

01

Testing

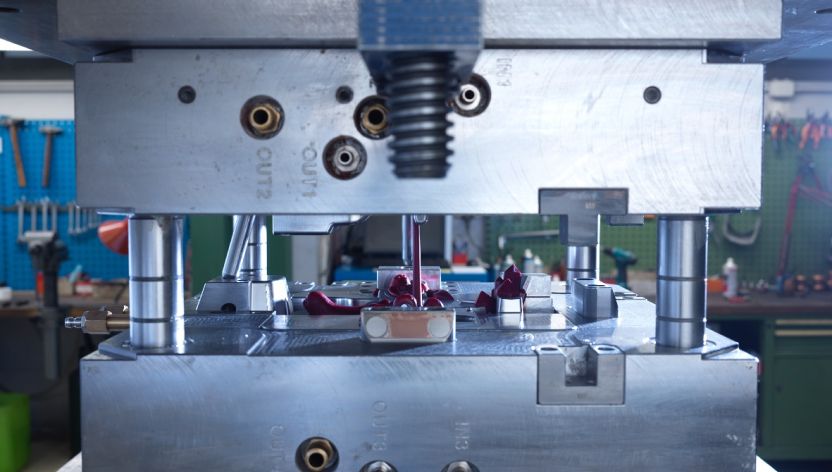

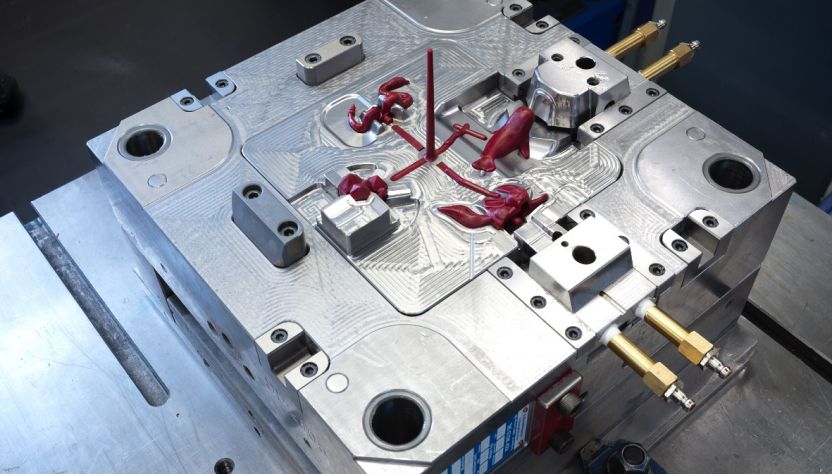

All molds produced are tested twice. The first is conducted on the bench with the aid of a vertical Die Spotting machine with wax injector, allowing us to obsessively check every closure and critical point. The second test is done in an injection machine suitable to guarantee the maximum quality of the product.

02

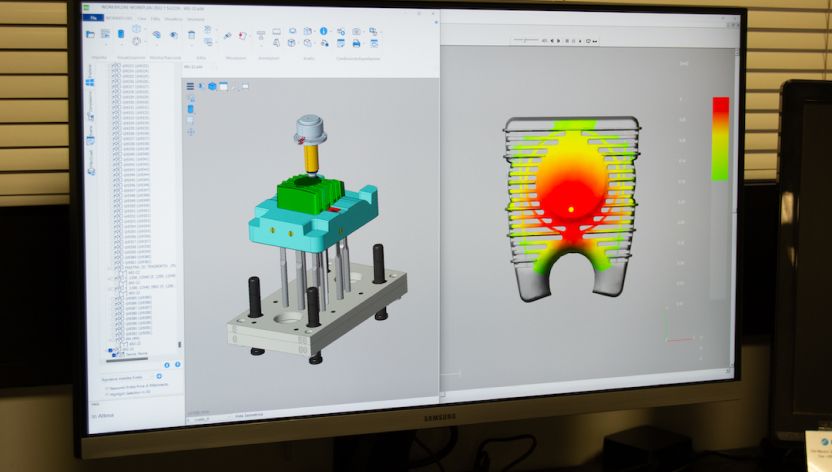

Filling analysis

During injection molding it is our practice to check the filling flow by making poor mouldings. This counter-analysis allows us to precisely identify anomalies and enhance our comparison database with mold flow analysis. Because the experience must be constantly powered!

03

Molding cycle

Our sampling department is equipped like a molding department: presses with dedicated dehumidifier, single-phase feeders, volumetric burners, linear manipulators and conveyor belts. We leave nothing to chance and, upon request, we can simulate a 360° molding cycle. Furthermore, we are also able to satisfy production peaks with pre-series.

04

Dimensional control

In 2022 we embarked on a complete renovation and expansion of our internal metrology laboratory. Zeiss coordinate measuring machine, altimeter, durometer, thermometer, microscope and more.

Request a consultancy

-

(+39) 0444 75 07 86

-

(+39) 0444 75 90 35

-

This email address is being protected from spambots. You need JavaScript enabled to view it.

-

FESP MOLD SRL - Construction of molds for plastic materials

Via Meucci, 10 – 36066 Sandrigo (VI)

Next step

With a solid method built over the years we are able to create high precision projects for the mass production of products of any company, from the food to the automotive sector.