Injection Moulding with Recycled Plastics: Why You Need a Dedicated Mould and How to Reduce Waste

The use of recycled and reprocessed materials in injection moulding is increasing rapidly. Companies are looking to reduce environmental impact, meet regulatory demands and improve the sustainability profile of their products.

However, moulding with recycled plastics is not the same as moulding with virgin material.

Higher variability, lower melt stability and different flow behaviour require a specific engineering approach.

In this article, we explore:

-

why recycled plastics behave differently in injection moulding

-

how waste affects degradation and process stability

-

what “material persistence” means in recycled polymers

-

a real case: custom micro-shutters engineered by Fesp Mold

-

the technical benefits of designing the mould around the material

Recycled Plastics vs Virgin Material: What Changes in Injection Moulding

Recycled polymers come with a level of unpredictability that virgin materials simply do not have. Key differences include:

-

greater variability between production batches and suppliers

-

less consistent flow characteristics (MFI/MFR variations)

-

higher sensitivity to dimensional tolerances

-

reduced melt stability during the cycle

Using a mould designed for virgin material often leads to:

-

unbalanced or inconsistent filling

-

higher scrap rate

-

dimensional instability

-

more frequent parameter adjustments

-

overall process unpredictability

For this reason, moulds used with recycled plastics must be engineered around the specific behaviour of the material.

Why Waste Reduction Is Even More Critical with Recycled Materials

Waste reduction is always important in injection moulding — but with recycled polymers, it becomes a decisive factor for process quality.

1. Accelerated thermal degradation

Every heating cycle contributes to further degradation of the polymer chain.

When scrap or sprues are reintroduced into the process:

-

melt stability decreases

-

viscosity changes

-

mechanical properties decline

A material that has already been recycled once will degrade faster when reprocessed again.

2. Material persistence in the process

With recycled or reprocessed polymers, every sprue, runner or rejected part becomes new recycled content re-entering the material stream.

This increases what we call material persistence: the tendency of recycled polymer to remain in the process over multiple cycles, gradually becoming:

-

less stable

-

less predictable

-

more sensitive to shear and temperature fluctuations

3. The vicious cycle of variability

More regrind → less melt stability → more defects → more scrap → more unstable material in the system.

A loop that can only be broken with proper mould design that limits cold runners and unnecessary thermal cycles.

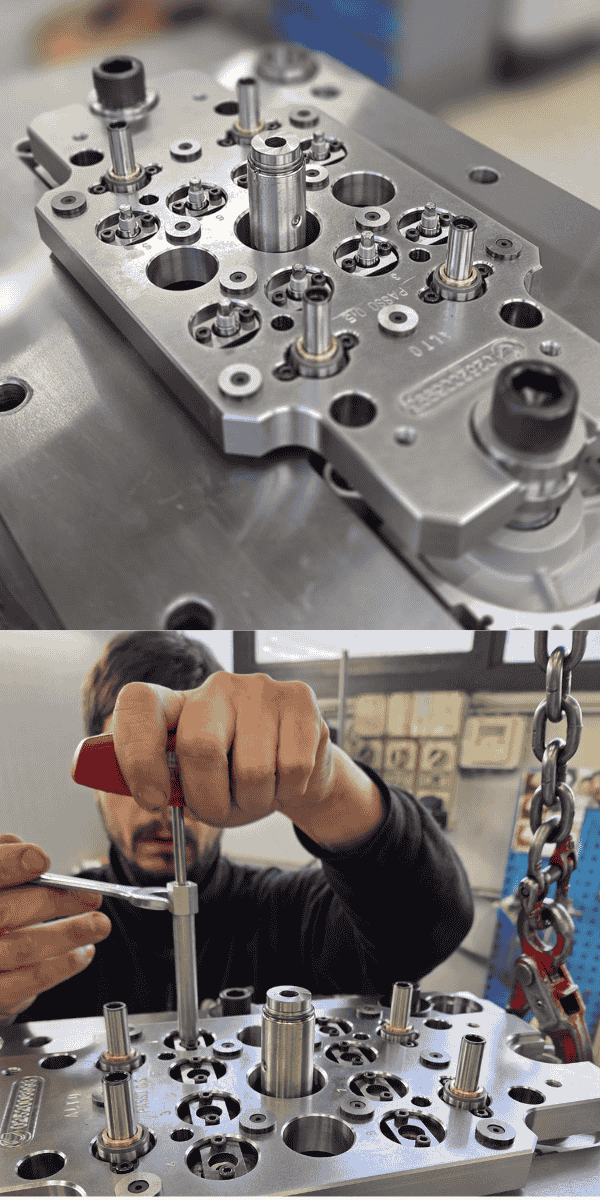

A Real Case Study: Custom Micro-Shutters to Improve Process Stability

A customer working with recycled and reprocessed polymers approached Fesp Mold with a clear objective:

👉 minimise scrap and ensure long-term stability of the moulded parts.

To avoid cold sprues, which would inevitably generate more regrind, our engineering team developed:

➡️ Custom-designed micro-valve nozzles

This solution allowed us to:

-

eliminate cold runners

-

precisely control the flow and filling phase

-

stabilise cavity-to-cavity behaviour

-

reduce backpressure and cycle variability

-

maintain consistent part quality despite material variability

Technical Benefits of a Mould Designed for Recycled Plastics

A mould engineered specifically for recycled materials can deliver significant improvements:

✔ More stable and predictable cycles

✔ Consistent part quality even with variable material

✔ Lower scrap rate, reducing material degradation

✔ Reduced machine downtime and fewer adjustments

✔ Higher overall process efficiency

In short: moulding recycled plastics successfully depends on the mould’s ability to respect and adapt to the material’s inherent behaviour.

The Fesp Mold Approach: Designing the Mould Around the Material

At Fesp Mold, every mould design begins with a detailed understanding of the polymer being used:

-

flow behaviour (melt index, viscosity, rheology)

-

thermal stability

-

shear sensitivity

-

melt degradation risks

-

additives and reprocessing history

This allows us to engineer tailored solutions, such as custom micro-shutters, optimised hot runner systems, advanced balancing strategies, that ensure stable processes even with recycled, reprocessed or bio-based polymers.

Moulding with recycled materials requires: greater process control, dedicated mold design, careful management of scrap and thermal cycles

With the right engineering approach, it is possible to achieve stable processing, consistent quality and reduced material degradation.

The key is clear:

design the mould around the material, not the other way around.

If you are evaluating recycled materials or looking to optimise an existing mould, Fesp Mold can support you with technical analysis, customised design and tailored engineering solutions.