A great product design is not enough. If your mold isn’t engineered with the same level of care, you could be losing margin at every stage of production.

The effects of a poor-performing mold become clear over time:

- Higher scrap rates

- Unexpected machine downtime

- Longer cycle times

➡️ Increased operational costs

The hidden cost of the wrong mold

Every defective part, every unscheduled stop, every extra second in the cycle eats into your profits. And often, these costs are not immediately visible.

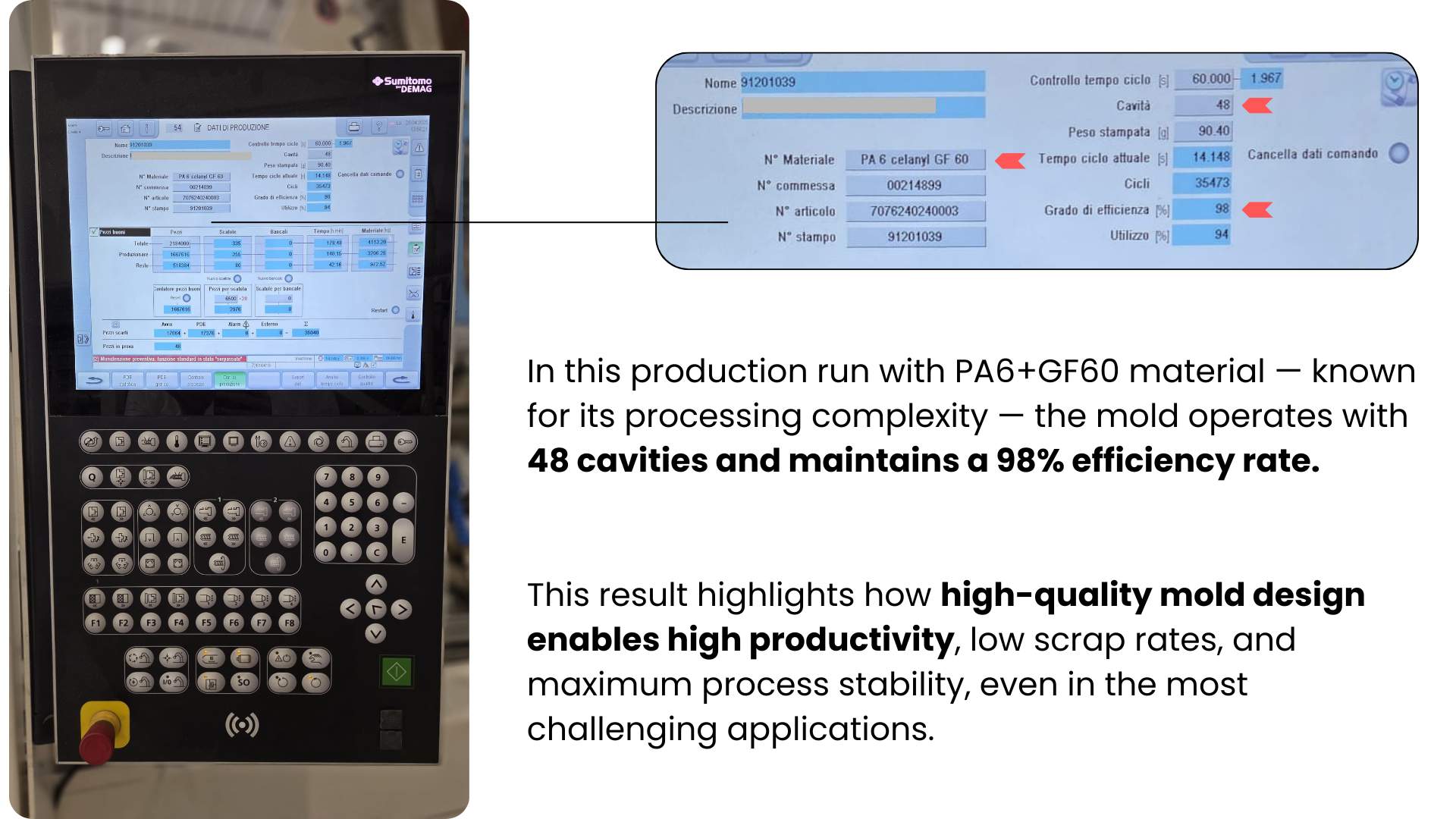

Investing in a high-performance, precision-engineered mold means:

- Reducing scrap through consistent quality

- Minimizing downtime thanks to stable tolerances and robust design

- Optimizing energy consumption and cycle efficiency

➡️ Improving margin per part produced

It’s a matter of perspective: focusing only on the initial price is short-sighted. Looking at the Total Cost of Ownership transforms a cost into a long-term investment.

Looking for a mold that truly improves your margins?

We design high-performance, multi-cavity molds to reduce operational costs and boost your production efficiency.

📩 Get in touch with one of our technical specialists